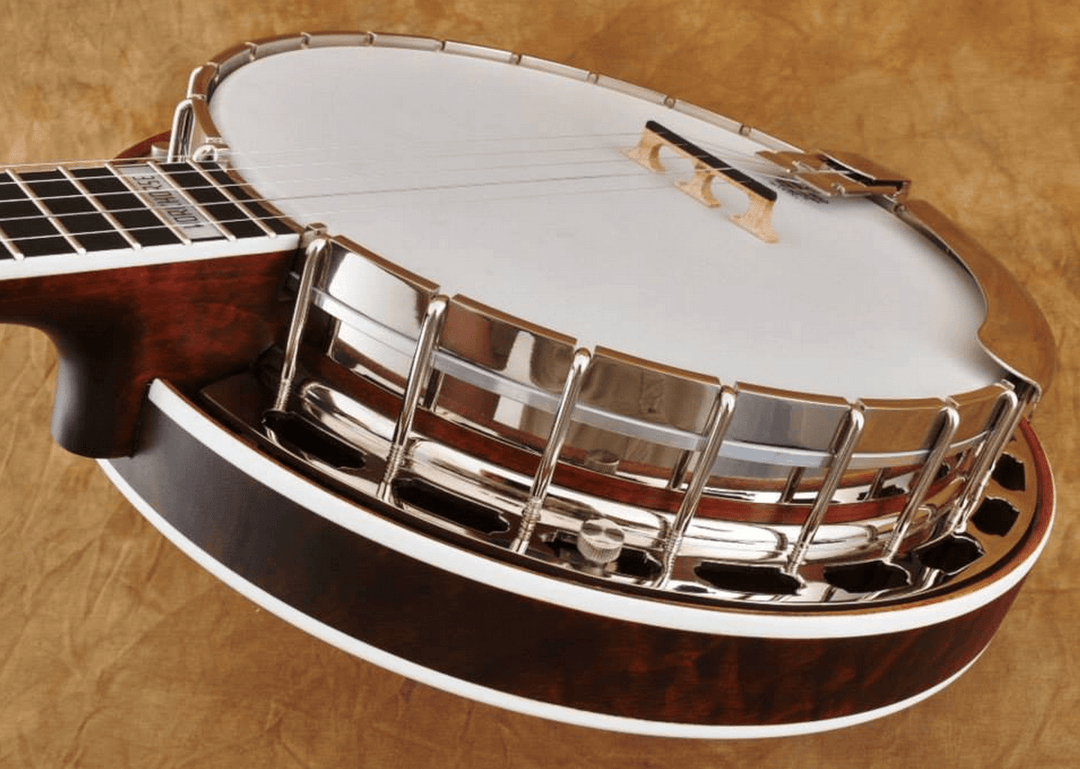

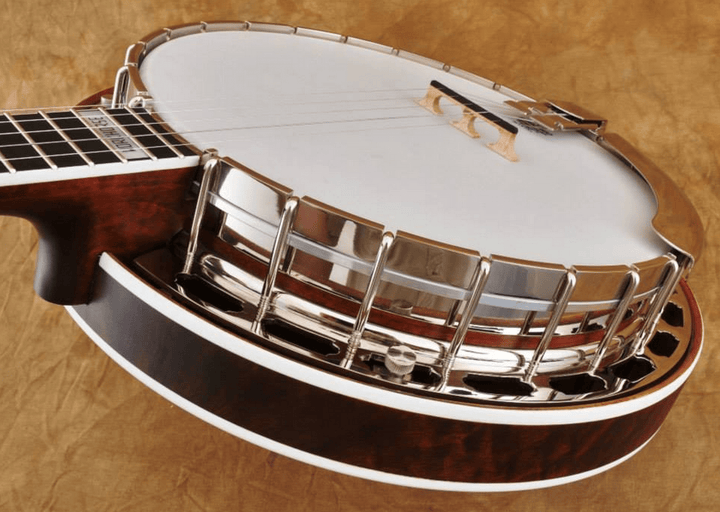

Classic Bluegrass Banjo Tone

Huber’s new Workhorse line of banjos feature Huber’s legendary build quality, playability, and tone, but at a more affordable price point.

The Workhorse is built in the same Tennessee shop as their Truetone line. It has an 844 brass alloy tone ring made in the same foundry as their famous HR-30 pre-war rings.

The banjo features a satin finish, ebony fingerboard, and a one-piece flange with nickel plating.

- Huber 844 Tone Ring and Vintage Rim

- Curly Maple Neck & Resonator

- Satin finish on Neck and Resonator

- Bright Nickel-Plated Parts

- Ebony fingerboard

- Genuine Mother-of-Pearl “1941 Leaves & Bows” inlay

- White Binding on Neck & Resonator

- Presto Tailpiece

- Waverly V-2 Tuners

- Huber Head & Bridge

- Huber LIFETIME Warranty

From BluegrassToday.com - John Lawless, July 22, 2014

Huber Banjos has been known for building prewar replica banjos of the highest quality, for the most discriminating players. But their newest model, dubbed The Workhorse, sets a different goal.

Officially introduced this week, their latest entry is designed to offer the quality workmanship that has been Huber’s hallmark at a price more attractive to budget-minded pickers. It’s what they call an entry-level, professional grade banjo, made in their shop near Nashville, TN by the same team that builds the vaunted Truetone line.

A curly maple banjo, made with a Huber tone ring, rim, neck and resonator. They aren’t the same components as used in the Truetone models costing twice as much, but still manufactured to Huber’s specs. The tone ring is made from an 844 brass alloy, often called “red brass,” rather than the prewar formulation, and is cut in the Huber shop to prewar dimensions. It is fitted to a 3 ply rim made by Brian Sims in the Huber facility in Louisiana where their Engineered Rims are constructed.

Joe Spann at Huber Banjos tells us that they can offer such a pro level banjo at this price by controlling labor costs.

“We are able to produce the Workhorse banjo at this price point because we are building them in batches. We are using ebony fingerboards, a satin nitro-cellulose lacquer finish and offering only one option (mahogany or curly maple wood). We have reduced our labor cost in the Workhorse, but the quality will remain at the same level Huber banjos are known for.

The banjo has a classic pre-war look (because we love pre-war banjos) with a double-cut peghead and our 1941 leaves & bows inlay pattern.”